탭밀도측정기

Tap density meters (Copley)

Tapped Density Testers

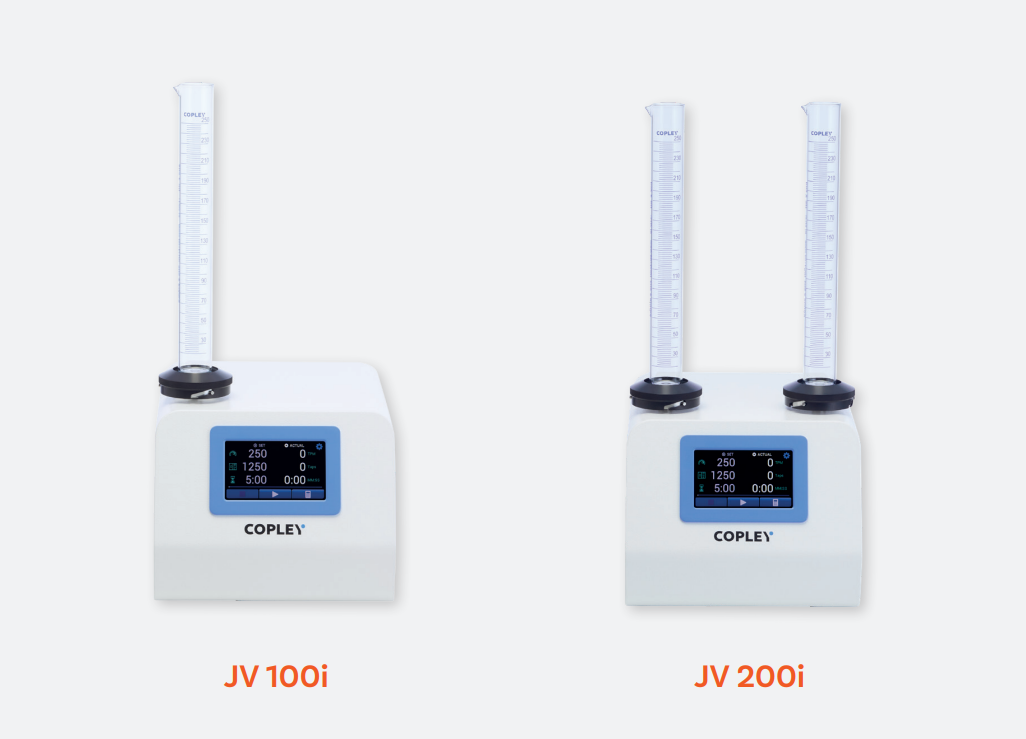

- A high reliability solution for routine measurement of the tapped density of powders, granules and similar products, the Copley JVi testers are the only single tapped density systems on the market that offer all three methods specified in Eur. Ph. and USP.

Testers

- Available with either one or two test stations, the JVi tapped density series provides detailed reports, including Hausner ratio calculations for a wide range of industrial standards.

-

-

1. Ph. Eur. and USP Compliant, Pharmaceutical Testing

2, Supports Methods 1, 2 and 3

3. Integrated calculation of bulk density, tapped density, Hausner ratio and compressibility index

4. Intuitive touchscreen control to simplify operation

5. Extensive data reporting output options

6. Adjustable stroke frequency control for accelerated or high sensitivity testing.

7. one to two test station unit configurations

8. Option to automate and remotely control JVi systems

-

1. Ph. Eur. and USP Compliant, Pharmaceutical Testing

JVi Series: Key Features

-

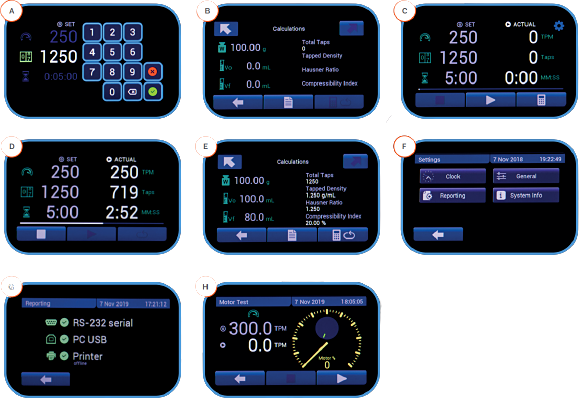

• Intuitive menu structure enables users to locate features quickly and easily

• Easy-set user-configurable test parameters:

Test speed

Number of taps

Test duration

• Status of ‘Actual’ v ‘Set’ test parameters clearly displayed throughout testing

• Test progress bar provides clear and constant indication on run status

• Resistive touchscreen interface can be operated with gloves on

• Hygienic wipe-clean screen

• High productivity - easy system set-up and operation minimises training burden.

-

JVi Series: Touchscreen User Interface

Fully automatic solutions

| JV 100i | JV 200i |

|---|---|

| Cat Number 1631 |

Cat Number 1632 |

| Test Station Capacity 1 Cylinder |

Test Station Capacity 2 Cylinders |

| Eur. Ph and USP Test Methods Supported 1, 2, 3 |

Eur. Ph and USP Test Methods Supported 1*, 2, 3 (* Only one station available for this method) |

| Unit Dimensions (w x d x h) 260 x 347 x 562 mm (with 250 mL cylinder) |

Unit Dimensions (w x d x h) 260 x 347 x 562 mm (with 250 mL cylinders) |

JVi Series: Technical Specifications

| Pharmacopoeial Compliance | Ph. Eur. 2.9.34 USP [616] |

|---|---|

| User Interface | Resistive touchscreen |

| Test Duration Parameters | Time or Taps |

| Testing Run Time | Up to 99 hours, 59 minutes, 59 seconds |

| Test Station Capacity | Up to 2 stations (1 left, 1 right) |

| Data Output | RS 232 USB Type A (for a USB printer) USB Type B (for communications with a PC) |

| Methods Supported Details | Method 1: 14 mm @ 300 taps/min Method 2: 3 mm @ 250 taps/min Method 3: 3 mm, 14 mm – 50/60 taps/minute |

| Alarm | End of testing (audible) |

| Cat. No. | Description |

|---|---|

| 1631-1 | Tapped Density Tester JV 100i – Method 1, 250 mL Cylinder |

| 1631-2 | Tapped Density Tester JV 100i – Method 2, 250 mL Cylinder |

| 1631-3 | Tapped Density Tester JV 100i – Method 3 - 3mm Drop |

| 1631-4 | Tapped Density Tester JV 100i – Method 3 - 14mm Drop |

| 1632-2 | Tapped Density Tester JV 200i – Method 2, 250 mL Cylinders |

| 1632-3 | Tapped Density Tester JV 200i – Method 3 - 3mm Drop |

| 1632-4 | Tapped Density Tester JV 200i – Method 3 - 14mm Drop |

| 1604 | 250 mL Measuring Cylinder (spare) |

| 1605 | 100 mL Measuring Cylinder (option) |

| 1635 | Tapped Density Method 3 Cup |

| 1643 | Platform for use with 250 mL Cylinder – Method 1 |

| 1644 | Platform for use with 250 mL Cylinder – Method 2 |

| 1641 | Platform for use with 100 mL Cylinder – Method 1 |

| 1642 | Platform for use with 100 mL Cylinder – Method 2 |

| 1645 | Platform for use with Cup – Method 3 - 3mm Drop |

| 1646 | Platform for use with Cup – Method 3 - 14mm Drop |

| 1636 | Acoustic Cabinet for JV100i / 200i |

| 1609 | 50 mL Measuring Cylinder Kit |

| 1610 | 25 mL Measuring Cylinder Kit |

| 1611 | 10 mL Measuring Cylinder Kit |

| 1612 | 5 mL Measuring Cylinder Kit |

| 1603 | IQ/OQ/PQ Documentation Pack |

| 1616 | Qualification Tools |

| 1617 | Re-calibration of Qualification Tools |

Powder Flowability Angle of Repose_compressed.pdf

Powder Flowability Angle of Repose_compressed.pdf