Particle Size & Shape analyzer

ACCURATE MEASUREMENT OF MATERIAL QUALITY.

Particle Size & Shape analyzer

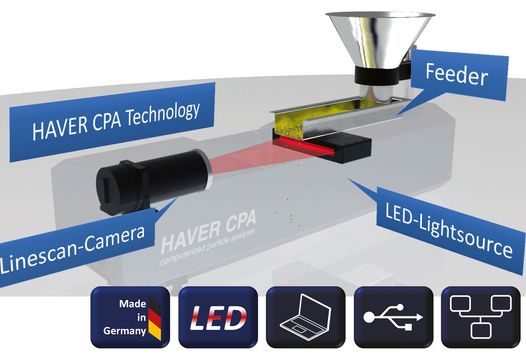

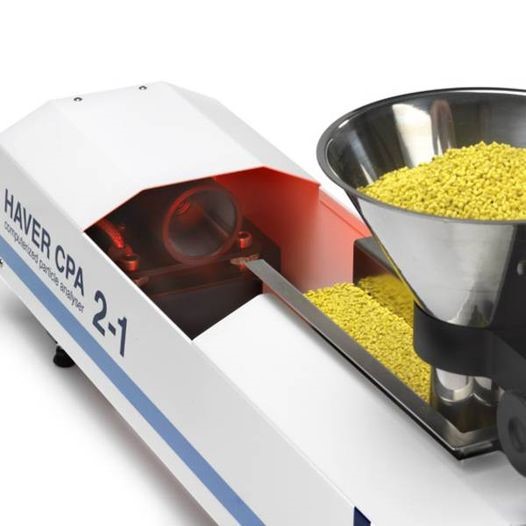

HAVER CPA Technology

The HAVER CPA measuring process is used for dynamic image analysis of grain sizes and grain shapes of dry and non-agglomerating particles of bulk materials. When fitted with the appropriate HAVER peripherals, this process can be used as a laboratory, technical centre or online version in different fields: gravel, sand, coke, coal, plastic granules, wood chippings, chemical and pharmaceutical products, fertilizers, foodstuffs and many more.

|

|

Extract from the particle list |

|

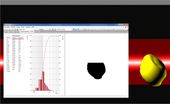

The real time evaluation |

|

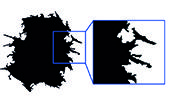

Highly precise particle size detection |

|

HAVER CpaServ Software |

|

제품소개

| HAVER CPA 2-1 HR | |

|---|---|

|

|

| Application examples for the HAVER CPA 2-1 HR | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

||||||||||||||||||||||

| HAVER CPA 2-1 - suitable for monitoring product quality | |

|---|---|

|

|

| Application examples for the HAVER CPA 2-1 | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

||||||||||||||||||||||

| HAVER CPA 2 CONVEYOR | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

||||||||||||||||||||||||

| Application examples for the HAVER CPA 2 CONVEYOR | |

|---|---|

|

|

| HAVER CPA 2-1 ONLINE | |||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||

| Application examples for the HAVER CPA 4-1 | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

||||||||||||||||||||||

|

|

||||||||||||||||||||||

| Application examples for the HAVER CPA 4-2 | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

||||||||||||||||||||||

|

|

||||||||||||||||||||||||

| Application examples for the HAVER CPA 4 CONVEYOR | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

||||||||||||||||||||||||

Dynamic Image Analysis-All CPA models.pdf

Dynamic Image Analysis-All CPA models.pdf