입자ㆍ입도ㆍ분체 특성장비

음파식 체 분급기

Sonic sifter separator

VariSifter™

A superior sieving instrument, the Sonic Sifter Separator is precise, versatile and ideal for research and quality assurance applications. It’s especially effective with “difficult” dry powder materials previously considered too fine for particle analysis

음파식 체 분급기

Sonic sifter separator

Sonic sifter separator 특징

features / benefits

features / benefits  Additional Sonic Sifter Features and Benefits.

Additional Sonic Sifter Features and Benefits.- • Sieving action can be varied for different densities and textures of materials.

- • Sieving can be timed automatically to ensure repeatable results.

- • Separated fractions of material (even below 5 micrometers) are retrievable for further evaluation after the analysis is complete.

- • All sieves can be conveniently direct-tared on conventional analytical balances, eliminating the need to transfer retained samples for mass determination.

- • Special see-through acrylic-framed sieves allow operator to determine proper power level and finish point for testing.

- • Power level to separate particles is infinitely adjustable by operator as test progresses.

- • A vertical, oscillating column of air 'tries' the particles 60 times per second on the screening surface, and a vertical mechanical pulse shears agglomerates (as in many conventional sieve shakers). The sifter then reorients the particles in the air column.

- • No horizontal 'scrubbing' of the particles occurs as on standard sieve shakers. This scrubbing is the largest single cause of particle breakdown or attrition.

- • Operation requires a very short learning curve.

- • The unit is virtually maintenance-free, with no need for periodic adjustments or recalibration.

- • The unit has a capacity of up to six standard sieves or three precision mesh, double height sieves.

A Powerful Tool: The Original Sonic Sifter Separator

A Powerful Tool: The Original Sonic Sifter Separator- A superior sieving instrument, the Sonic Sifter Separator is precise, versatile and ideal for research and quality assurance applications. It’s especially effective with “difficult” dry powder materials previously considered too fine for particle analysis.

-

Specially designed 3" (75mm) diameter acrylic-frame and a patented oscillating air column allows this unit to achieve efficiencies previously seen only with wet sieving for materials in powdered, granular or pellet form and is capable of achieving separations over the range of 3μm to 5.6mm. .bmp)

- • A unique oscillating air column moves even the finest particles through a stack of screens.

- • The Sonic Sifter is virtually maintenance free.

- • Quiet operation makes this unit suitable for most laboratory installations.

- • There’s no screen wear or particle attrition.

- • Digital timer for precise operation.

- • Capacity of six standard or three precision sieves per test run.

- Particle separations can be accomplished in less than 10 seconds under favorable conditions. And testing times can be cut by up to 90%, compared to other methods.

Sonic sifter separator 제품소개

Sonic Sifter Separator

Sonic Sifter Separator  A Powerful Tool:The Original Sonic Sifter Separator.

A Powerful Tool:The Original Sonic Sifter Separator.- A superior sieving instrument, the Sonic Sifter Separator is precise, versatile and ideal for research and quality assurance applications.

- Specially designed 3.5" (75mm) diameter acrylic-framed sieves and a patented oscillating air column allows this unit to achieve efficiencies previously seen only with wet sieving for materials in powdered, granular or pellet form ? and is capable of achieving separations over the range of 3μm to 5.6mm.

- The Sonic Sifter is virtually maintenance free. There’s no screen wear or particle attrition. Particle separations can be accomplished in less than 10 seconds under favorable conditions. And testing times can be cut by up to 90%, compared to other methods.

With the Sonic Sifter

With the Sonic Sifter- • Action can be varied for different densities and textures.

- • Automatic timing ensures repeatable results.

- • Separated fractions of material are retrievable.

- • All sieves can be conveniently direct-tared on conventional analytical balances.

- • Special see-through acrylic-framed sieves help determine proper power level and finish point.

- • Power level to separate particles is infinitely adjustable.

- • A vertical, oscillating column of air “tries” the particles 60 times per second, and a vertical mechanical pulse shears agglomerates and reorients the particles in the air column.

- • No horizontal scrubbing of the particles occurs as in standard sieve shakers.

- • Operation requires a very short learning curve.

- • There’s no need for periodic adjustments or recalibration.

- • Unit holds up to six standard sieves or three precision mesh, double height sieves.

![]() Pricing

Pricing

| Model L3P | (120vac. 60Hz) |

| Model L3P-15 | (120vac. 50Hz) |

| Model L3P-25 | (240vac, 50Hz) |

| Model L3P-26 | (240vac, 60Hz) |

| * Includes: Complete stack assembly, electrical line cord for operation and instruction manual. Sieves required for operation are not included, but can be ordered from the table on the other side. | |

![]() Basic Specifications

Basic Specifications

- • Power Requirements

-

Model L3P 120 volts, 60 cycles Model L3P-15 120 volts, 50 cycles Model L3P-25 240 volts, 50 cycles Model L3P-26 240 volts, 60 cycles Consumption 100 Watts

- • Operating Ranges

-

Temperature 0º to 120º F (-18º C to 49º C) Humidity any (non-condensing) * For best results, temperature and humidity should be controlled.

- • Dimensions

-

Weight 43 lb (20 kg) Cabinet 10"w x 12"d x 23"h

25 cm x 31 cm x 61 cm

- • Built-in digital timer

![]() Warranty

Warranty

- • Limited one-year warranty on all units

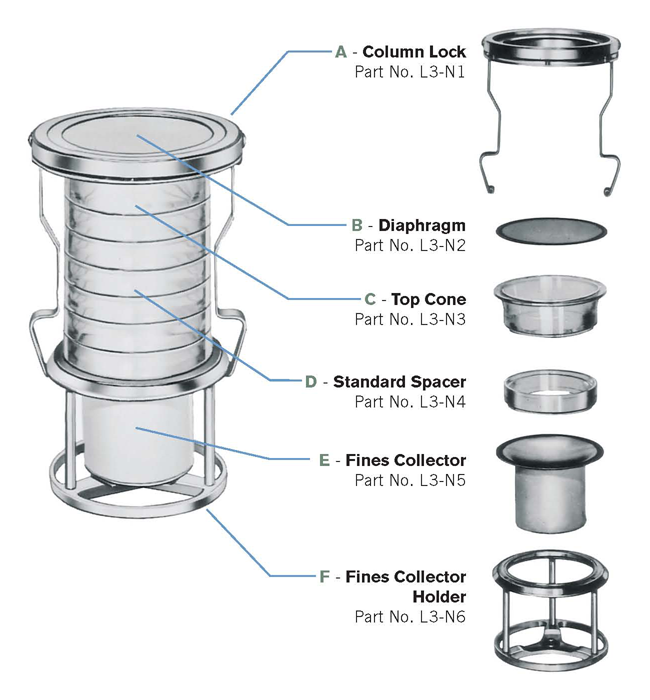

Sonic Sifter Separator Accessories

Sonic Sifter Separator Accessories| Item | Description | Part Number | Unit Price |

|---|---|---|---|

| A | Column Lock | L3-N1 | |

| B | Diaphragm | L3-N2 | |

| C | Top Cone | L3-N3 | |

| D | Standard Spacer | L3-N4 | |

| E | Fines Collector | L3-N5 | |

| F | Fines Collector Holder | L3-N6 | |

| Complete Stack Assembly* | L3-N7 | ||

| * Includes column lock, diaphragm, top cone, six standard spacers, fines collector and fines collector holder. | |||

The Model L3-N8 Horizontal Pulse Accessory

The Model L3-N8 Horizontal Pulse Accessory A must for accurate separations below 45μm, this electromechanical device eliminates agglomerates in extremely fine powders. A tapping action alternates on opposite sides of the screen frame to create a high speed shock wave, breaking down agglomerated materials and reintroducing near-sized particles back into the air stream, and then back onto the screening media.

A must for accurate separations below 45μm, this electromechanical device eliminates agglomerates in extremely fine powders. A tapping action alternates on opposite sides of the screen frame to create a high speed shock wave, breaking down agglomerated materials and reintroducing near-sized particles back into the air stream, and then back onto the screening media.

(110 vac 50 or 60 HZ)

| Includes: Power supply with electrical line cord for 110 volt operation, machined pulse assembly designed to fit in the sieve stack of the Sonic Sifter Separator. |  |

U.S. Standard Sieves 3" (76.2 mm) Diameter

U.S. Standard Sieves 3" (76.2 mm) Diameter- • U.S. Standard sieves listed meet the current sieve specifications of ASTM and ISO.

- • Supplied with Certificate of Compliance to U.S. and International Standards.

- • Available in stainless steel and brass mesh where noted.

- • Clear acrylic frame dimensions: 3-1/2" O.D., 3" I.D. with an overall height of 5/8".

| U.S. Sieve No. | Opening Size | Catalog Number Stainless Steel | Catalog Number Brass | Unit Price |

|---|---|---|---|---|

| 3.5 | 5.60mm | L3-S3.5 | L3-B3.5 | |

| 4 | 4.75mm | L3-S4 | L3-B4 | |

| 5 | 4.00mm | L3-S5 | L3-B5 | |

| 6 | 3.35mm | L3-S6 | L3-B6 | |

| 7 | 2.80mm | L3-S7 | L3-B7 | |

| 8 | 2.36mm | L3-S8 | L3-B8 | |

| 10 | 2.00mm | L3-S10 | L3-B10 | |

| 12 | 1.70mm | L3-S12 | L3-B12 | |

| 14 | 1.40mm | L3-S14 | L3-B14 | |

| 16 | 1.18mm | L3-S16 | L3-B16 | |

| 18 | 1.00mm | L3-S18 | L3-B18 | |

| 20 | 850μm | L3-S20 | L3-B20 | |

| 25 | 710μm | L3-S25 | L3-B25 | |

| 30 | 600μm | L3-S30 | L3-B30 | |

| 35 | 500μm | L3-S35 | L3-B35 | |

| 40 | 425μm | L3-S40 | L3-B40 | |

| 45 | 355μm | L3-S45 | L3-B45 | |

| 50 | 300μm | L3-S50 | L3-B50 | |

| 60 | 250μm | L3-S60 | L3-B60 | |

| 70 | 212μm | L3-S70 | L3-B70 | |

| 80 | 180μm | L3-S80 | L3-B80 | |

| 100 | 150μm | L3-S100 | L3-B100 | |

| 120 | 125μm | L3-S120 | L3-B120 | |

| 140 | 106μm | L3-S140 | L3-B140 | |

| 170 | 90μm | L3-S170 | L3-B170 | |

| 200 | 75μm | L3-S200 | L3-B200 | |

| 230 | 63μm | L3-S230 | L3-B230 | |

| 270 | 53μm | L3-S270 | L3-B270 | |

| 325 | 45μm | L3-S325 | L3-B325 | |

| 400 | 38μm | L3-S400 | L3-B400 | |

| 450 | 32μm | L3-S450 | - | |

| 500 | 25μm | L3-S500 | - | |

| 635 | 20μm | L3-S635 | - |

Precision Sieves 3" (76.2 mm) Diameter

Precision Sieves 3" (76.2 mm) Diameter- • Precision sieves listed meet the current sieve specifications of ASTM E 161 and ISO.

- • Electroformed nickel mesh.

- • Clear acrylic frame dimensions: 3-1/2" O.D., 3" I.D. with an overall height of 1-1/4".

| Sieve Opening | Catalog Number | Unit Price | Sieve Opening | Catalog Number | Unit Price | |

|---|---|---|---|---|---|---|

| 3μm | L3-M3 | 3μm | L3-M3 | |||

| 5μm | L3-M5 | 5μm | L3-M5 | |||

| 10μm | L3-M10 | 10μm | L3-M10 | |||

| 15μm | L3-M15 | 15μm | L3-M15 | |||

| 20μm | L3-M20 | 20μm | L3-M20 | |||

| 25μm | L3-M25 | 25μm | L3-M25 | |||

| 30μm | L3-M30 | 30μm | L3-M30 | |||

| 35μm | L3-M35 | 35μm | L3-M35 | |||

| 40μm | L3-M40 | 40μm | L3-M40 | |||

| 45μm | L3-M45 | 45μm | L3-M45 | |||

| 50μm | L3-M50 | 50μm | L3-M50 | |||

| 55μm | L3-M55 | 55μm | L3-M55 |